This is a frequently asked question on the TDP range. This range of single station pill press includes the TDP 1.5, TDP 5 and TDP 6s. The machines are very similar and the main distinction between them is the pressure that is exerted during tablet making.

Articles Excipients

What Is The Importance Of Blend Uniformity In The Pharmaceutical Industry

In the pharmaceutical manufacturing process, it is important that blend uniformity be achieved. If there is poor uniformity, the product can be rejected based on weight or punch pressure causing loss of revenue to the your business. In this article we talk about how to overcome this problem.

Where Tableting Technology Is Heading

The industry has been undergoing revolution lately with the increase in the number of patents expiring and the growth of generic producers as well as increase in contract manufacturers. Another force is the increase in the competition with developing markets and other companies that are relocating their facilities to take advantage of these.

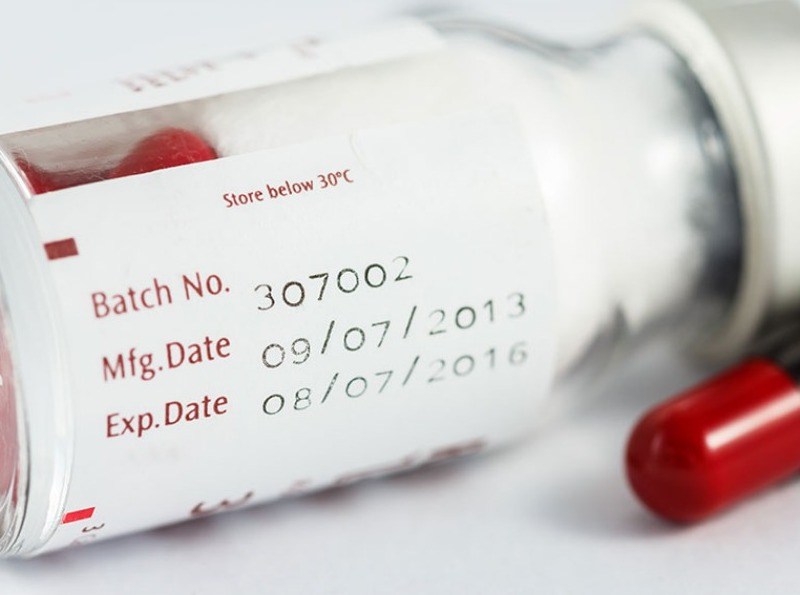

Why Do We Need Batch Production and Batch Numbers in Pharmaceutical Manufacturing?

A batch, according to the US FDA, means a specific quantity of a drug or other material that is intended to have uniform character and quality, within specified limits, and is produced according to a single manufacturing order during the same cycle of manufacture. A batch therefore is a specific amount of an API or other material that is processed in one or more ways so as to demonstrate homogeneity of the product.

Why Press 1 When You Can Press 8 for the Same Price

Multi-tip tooling equipment is not new in tablet making, in fact it has been used for more than a century. In the early years 1900s single station tablet presses could be fitted with multi-tip punches that could press two or more tablets at a time to help increase the production rate and at the same time lower labour costs, energy, reduce maintenance and conserve factory space.

Sign Up to Our Newsletter

Why You Should Make Your Own Supplements

First and foremost, making your own supplements is surprisingly simple to do. All you need are the tools and the ingredients. Of course recipes will also be required, but these can be found online with very little difficulty.

You may be thinking "but will it save me that much money?" and the answer yes! After the initial payments for the tools, it is possible to save over 90%. An individual who spends $100 a month on supplements could save over $1000 a year.

Why You Should Start A Supplement Company

Thinking about starting your own business? It's exciting but can also be slightly daunting. First finding the product or service you want to sell. Then raising capital, doing marketing, finding customers, sorting all the legal side of things. It all adds up and can appear complex and thats before you've even started.

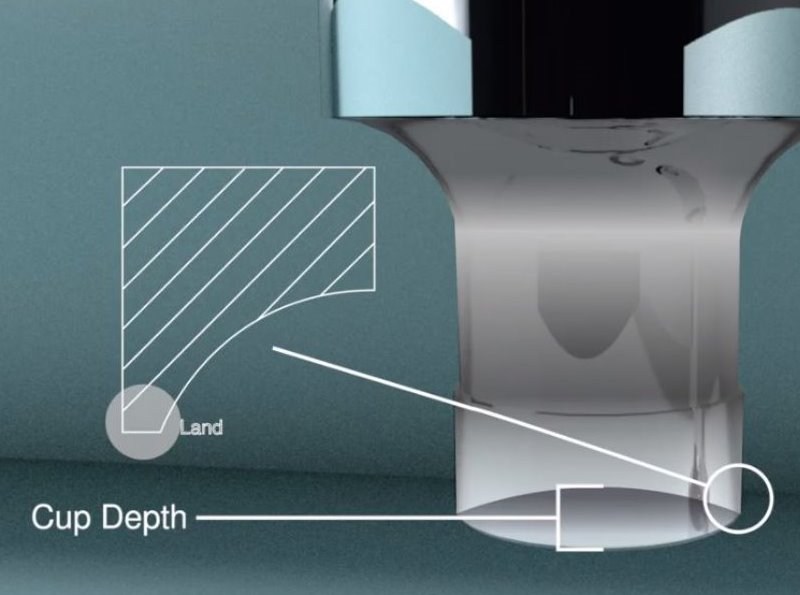

Cup and Tablet - Depth and Consistency

The cup depth is the space between the punch tip and the lowest possible measurable area of a cup cavity. In order to form proper inspection and wear limits of the tooling equipment, it is important that one should know about it, and how premature wear can affect the tablet.

Suggest Our Next Article

Can’t find what you are looking for? Let us know and we’ll add it to our article section

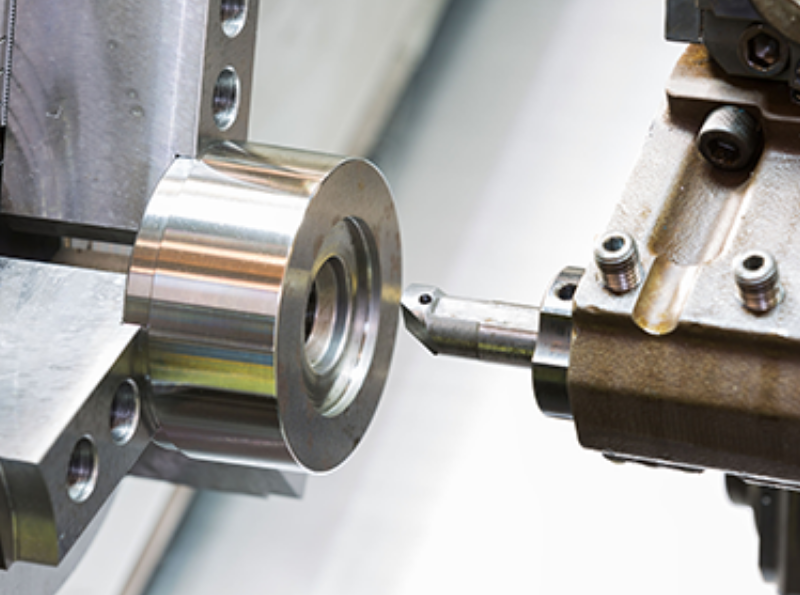

Tablet Tooling – How To Get The Biggest Punch

As the influx of new products invade the tablet press industry today, tablet manufacturers together with tooling vendors are constantly innovating the tablet compression technology. The article below discusses how the industry uses technology in determining the maximum compression force for tooling equipment.

What Are Flavored Gelatin Capsules

When it comes to choosing your capsules, have you ever heard of flavored gelatin capsules? It might conjure images of natural health practitioners or drug pharmacists; that said, average people could also purchase these capsule types. Flavored capsules has its advantages such as helping disabled individuals to take their medication and other benefits as well. In order to have an in-depth knowledge about flavored capsule, we have compiled some advantages of it below that you will find useful.