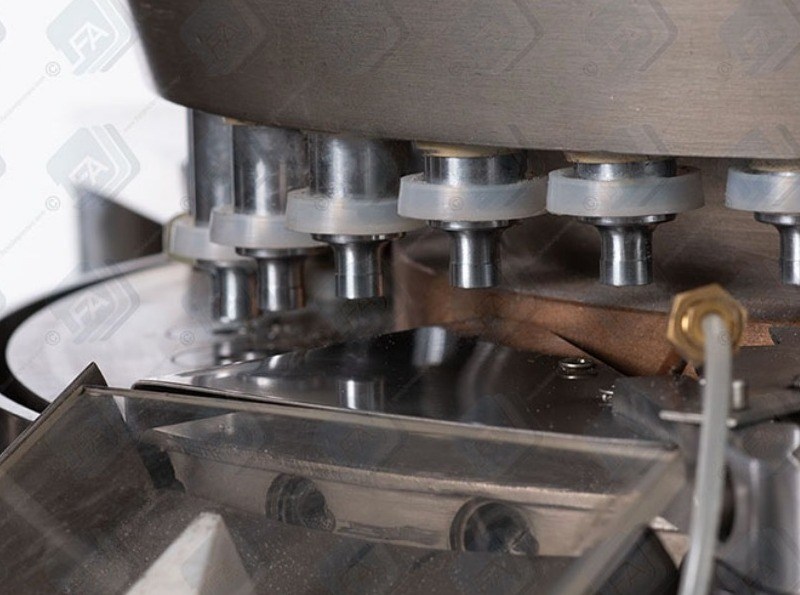

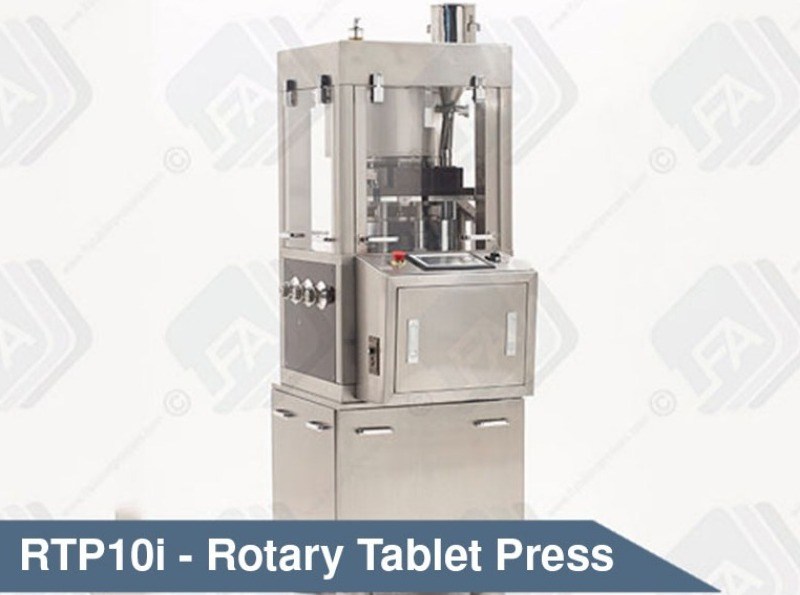

There are 2 types of tablet presses: single-punch and rotary tablet presses. Most high speed tablet presses take the form of a rotating turret that holds any number of punches and dies. As they rotate around the turret, the punches come into contact with cams which control the vertical position of each punch. Tablets produced by a rotary tablet press are compressed into uniform size, shape and weight making it the preferred machine for large-scale manufacture as it also produces more tablets than single punch machines.

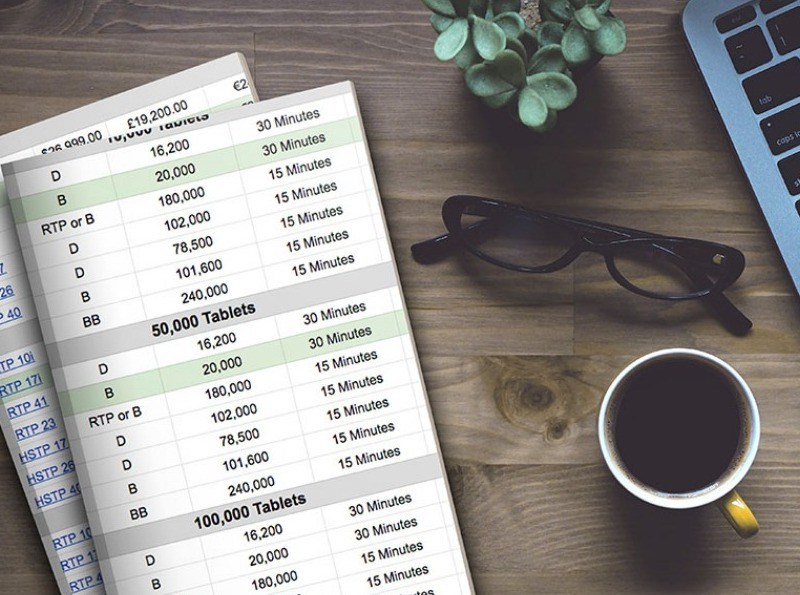

How To Prepare A Batch Manufacturing Record Template

A batch manufacturing record, or BMR, is a document containing the details of the manufacture of each product batch, across the whole manufacturing process. As there are many stages in the manufacturing process, each step must be recorded as proof, from obtaining the raw materials through to the final stage of packaging ready for sale. Any documents produced through the manufacturing process are then attached to the BMR as a record and proof of each stage.

What Should a BMR Contain?

The BMR should contain the batch record.

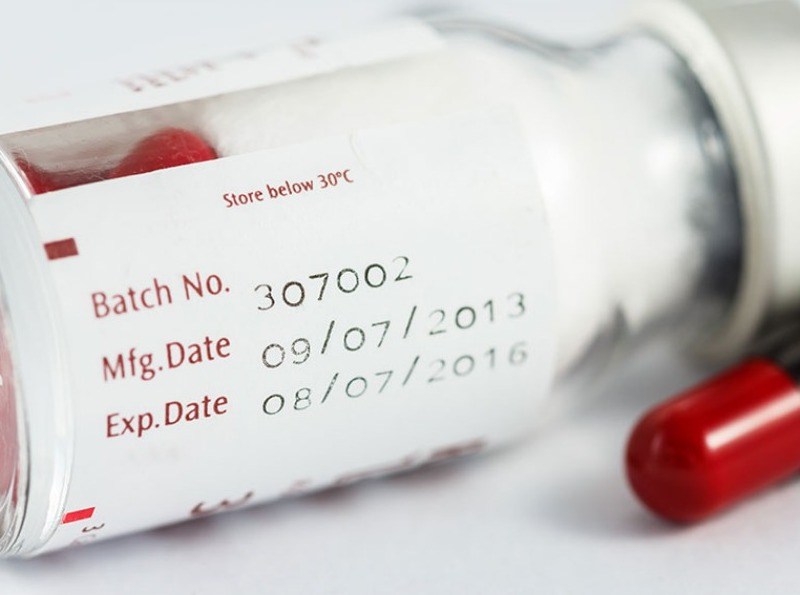

The first page should show the following:

- Batch number

- Composition

- Size and weight

- Storage conditions

- Master formula of the batch

- Start and completion date and expiry date

- Manufacturer’s licence number

Health and safety: the BMR should contain safety guidelines for the chemist and others who may be interacting with the product. The guidelines should cover the process used during manufacturing process and how to handle and equipment used.

Equipment safety and maintenance: a checklist should be included that covers the list of equipment used and proper procedures to clean and maintain such equipment. The cleaning process should be inspected and followed by the quality assurance personnel.

Material bill number: a list that includes the raw material and quantities used along with their AR number. Weight should also be checked for quality assurance. If tablets are coated, then the materials used to make these coatings should also be included.

Manufacturing procedure: the whole process of manufacture of the product should be described in a clear and systematic manner, in straightforward and easy to understand language. This includes: processing times for milling, sifting, drying, compression, lubrication, coating and packing. A line clearance checklist should be included to be followed before any new process is started. Once the final stages of the manufacturing process are reached, the products should be checked again to ensure that all guidelines have been followed and product specifications have been followed. The results of these checks should also be included in the BMR.

Yields: the total yield for each process should be calculated to determine the efficiency of the process. The final yield should not be less than 99%.

Abbreviations: any abbreviations used should be clearly defines and shown in the BMR.

History of changes: and revisions and changes to the document must be recorded and indicated throughout the document.

The BMR is vital for your HACCP plan and GMP / ISO 22000 / FDA / MHRA compliance. Every time a press is carried out on your machine, it should be added to the record.

Should you require more information, please get in contact and we will send it to you.