When people first think of tablet or pill presses they think pharmaceuticals, supplements, vitamins and minerals or just medicines. But tablet making machines can be used for other purposes.

Articles

Fluidized Bed Dryers And FBD Finger Bags – An Overview

Drying in the pharmaceutical industry involves the extraction of liquid and other liquid solvents from the materials or granules using air current or heat. Fluidized bed dryer is one of the equipment used to dry the granule particles using the FBD finger bag.

An Overview Of The Fluidized Bed Dryer

The Fluidized bed dryer is common in the pharmaceutical industry and widely used during the granulation process where granules undergo the drying process. The dryer allows the manufacturer to obtain the desired moisture content for the tablet formulation.

Five Facts You May Not Know about Vitamin D

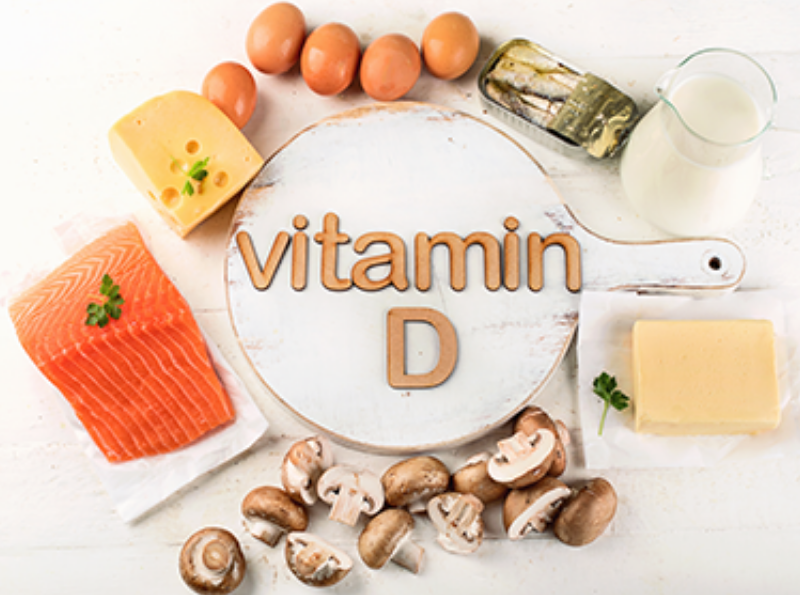

Vitamin D is necessary for maintaining good health, but 40 to 75% of the world's population is deficient. The vitamin is not found in many foods. Fortified milk, eggs, fish and beef liver are some of the few containing vitamin D and even in these the amounts may be small.

Film Coating Process In The Pharmaceutical Industry

The coating process plays a crucial role in tablet coating and many of the issues or problems arising come from the process setup. The different variables that affect the film coating should be addressed and how these variables play a crucial role in the coating process. The equipment type for film coating is also tackled in the article.

Facts You Should Know About Calcium Supplements

Calcium is a mineral that is an important component of the human diet for building strong bones and teeth, and also for regulating certain body processes.

Sign Up to Our Newsletter

Overview Of The Film Coating Process And Difference Between Solvent And Aqueous Coating

A single stage process, which results in quicker production. Minimal weight gain of tablets is at 2 – 3% compared with sugar coating which adds 60 to 80%. The film coat will not likely affect the tablet’s disintegration process.

One benefit of film coating is that it is easy to automate making it easier to comply with GMP requirements for Standard Operating Policy. It holds the ability to maintain its shape and allows for embossing.

Evaporating Pan or Steam Jacketed Kettle

The steam jacketed kettle or evaporating pan is an example of natural circulation evaporators. It is made up of a hemispherical shape with large surface area for the evaporation. The pan can be permanent and emptying is done through the outlet. The pan is mounted in a way that they can be tilted to take out the product. The pans are heated by the steam that comes out of the steam jacket.

An Overview of Encapsulating Liquids

Although one can encapsulate liquids in a gelatin or vegetarian capsule, the truth is that the process of encapsulating is both a science and an art. The product usually depends on the weight and quality of the formulation as well as other variables that can affect it.

Suggest Our Next Article

Can’t find what you are looking for? Let us know and we’ll add it to our article section

Easiest Way To Give Medicine To Your Pets

Pet owners can relate when it comes to the problem of giving medicine to one’s pet which can be a tough battle. As most capsules or pills have synthetic smell to it the tendency of the pet would be to refuse to swallow it. Some pets can be stubborn even running away once they see you coming.

Importance of Drug Regulations

Drugs are substances specifically recognised by an official Pharmacopeia and Formulary and approved for use to treat, diagnose, cure and prevent a disease or disorder. A substance induces change to the function and structure of the patient’s body.

The Different Dosage Forms Manufactured In The Industry

A drug is defined as a mixture of compounds used in the pharmaceutical industry to treat and prevent diseases. The different drug forms help health care providers to administer the drug safely. In this article LFA discusses the different forms of drug dosing and how best you can use them in your business.

Different Ways to Administer Drugs

Although LFA Tablet Presses specializes in Pill Presses and Tableting Equipment we understand that this is not always the best method of delivery. In this article we look into the other options available to you as a business with which to package and deliver your product.

Different Types Of Parenteral Preparations

Parenteral preparations are sterile pharmaceutical products administered to the human body by injection. Only liquids can be injected which means that the pharmaceutical parenteral preparation must either be a liquid which can itself be injected safely, or it may be a material that can be diluted with sterile water (commonly referred to as ‘water for injection’) or other sterile solvent before it is administered. Liquids other than water must not interfere with the stability and efficacy of the preparation. Some substances may be added to increase the stability and efficacy of the preparation, but it is important that such additives do not cause adverse effects or toxicity. Coloring agents are not permitted in parenteral preparations.

Different Temperature Sensors - Thermocouples, Thermistors, RTDs

Pharmaceutical companies make use of different temperature sensors due to their accuracy. Currently three sensors are widely used in the industry. Below is a brief on the three sensors.

Different Tooling Equipment For Oral Solid Dosage Tablets

Solid dosage forms are forms or shapes where drug mixtures are placed, example of which include tablets and capsules. These solid dosage forms are administered orally.

Tablets are defined as Solid Pharmaceutical Dosage forms that contain drug substances. They may contain suitable diluents or are prepared through moulding or compression.

11+ Tablet Coating Defects and their Remedies

https://www.lfatabletpresses.com/articles/tray-dryersCoating tablets with a thin polymer film can be an effective way to give your products a professional edge. High quality tablets can be quickly and easily produced using a tablet coating machine and the correct excipients . Unfortunately several defects can arise with coatings. The following list provides helpful remedies for common issues that may be encountered.

Solutions For Tablet Sticking

One of the major problems that the tablet manufacturing companies faces is tablet sticking. This problem occurs when the granulation sticks to the punch surface causing deformed tablets, which is very costly not only for the manufacturers but also for the formulators. One way to alleviate this problem is using analytical method as well as create screening processes. Authorities or field experts are also looking for ways to create analytical models to identify the solutions quickly for specific problems.