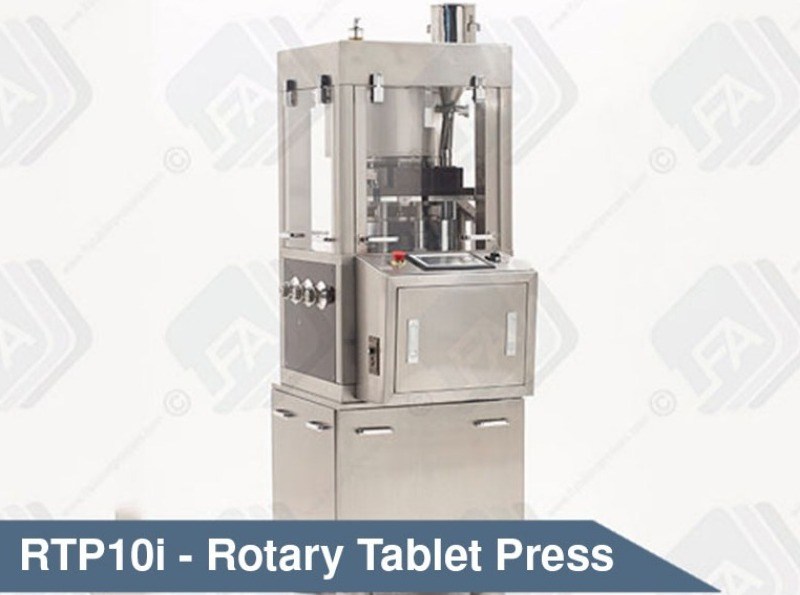

RTP10i Changing Cams

Welcome to LFA’s video on changing your RTP 10i Ejection and Fill cams. Overtime your ejection cams and fill cams will wear down so it’s important to inspect and change them when needed. We have a video on what to look out for on your cams which we’ll link in the description.

When working on your machine, always ensure there’s no power going to it.

To gain access to the lower cams we have to remove the hopper, force feeder and lower tooling.

First, stop the flow of formulation to the force feeder by adjusting the flow adjuster on the hopper. Turn this clockwise all the way in and this will stop the flow.

You can now lift the hopper out of the top of the machine. Once done, open the perspex shield and remove the hopper extender, this will still contain powder.

Using a 17mm spanner, undo the 2 bolts that attach the force feeder to the force feeder plate.

Now lift up the force feeder sheath with one hand and slide the force feeder towards you.

We’re now going to remove the dust extractor unit which is located at the rear of the machine and is secured by 2 bolts which can be removed with a 5mm allen key.

Now we’re going to remove the force feeder plate to give us more access to the lower turret shroud. Using a 6mm allen key, remove the 3 bolts on top of the plate. You can then remove the plate.

Remove only this adjuster to give us access to the bolt below it holding the lower turret shroud. Turn anti-clockwise to remove it.

Using a 5mm allen key remove the 4 bolts around the turret shroud.

Once the turret shroud is removed, we can start to remove the lower tooling. First access the inside the machine through the side panel. Push the puck inside up and out the top, ensuring the lower punch doesn’t fall.

Rotate the turret by hand and gently lower each lower punch out of the hole being careful not to damage the punches.

Now from under the machine you can undo the four 6mm bolts that will release the fill cam.

Undo the four 6mm bolts from the ejection cam, the one in the rear corner marked here has the shortest bolt, be sure to mark this. Slide out the ejection cam.

We can now be replace your new cams with four 6mm bolts on the fill cam and four 6mm bolts on the ejection cam, with the shortest bolt in the back corner, replacing the cams can be done in any order and individually, When re-tightening them always check your RTP10i manual for the recommended tensions.

Now we can start to replace the lower punches, enter the lower punches through the bottom of the machine up through the guide holes being extremely careful with the tips of the punches. You may feel some slight resistance as they enter but this is normal.

Now rotate the hand wheel so the punch isn’t over the hole, lower it so it’s flat on the surface. Now repeat this process for all of the lower punches.

Replace the puck, guide it in with your hand ensuring that it’s straight and run your fingers over it after to ensure its flush. After pull the tooling down flat on the surface.

Replace the turret shroud and tighten the four 5mm bolts with an allen key.

Replace the Dust Extraction unit, tightening the two 5mm bolts.

In this video we’re simply going to show you how to replace the force feeder, however since we’ve removed one of the adjusters the force feeder will likely need re-calibration. Our video to calibrating your force-feeder is in the description below.

Replace the force feeder adjuster with the non-threaded side facing upwards.

Replace the three 6mm bolts on the force feeder plate with an allen key.

Replace the force feeder onto the plate, ensuring this shaft is facing forwards so the force feeder sheath can easily pass over it. Now replace the two 17mm bolts with a spanner.

We can now replace our hopper extender through the side of the machine and our hopper through the top of the machine.

Now adjust the flow adjuster on the hopper to release the formulation down into the force feeder.

Now test the machine, always do this by hand first using the hand wheel and listen for any abnormal noises or any resistance whilst rotating.

As mentioned it’s important for your force feeder to be calibrated properly so please see our video on force feeder calibration.